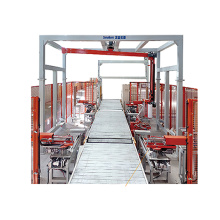

Silicone sealants sealing machine

| Détails d'emballage: | Wooden Cases Package and Container Transfer |

|---|---|

| productivité: | 100 sets per month |

| marque: | Jinan Lijiang Glass |

| transport: | Ocean,Land,Air,Others |

| Lieu d'origine: | Jinan City, Shandong Province, China |

| Capacité d'approvisionnement: | 100 sets per month |

| Certificats : | CE&ISO9000 |

| Hafen: | Qingdao Port,Tianjin Port,Shanghai Port |

Click on the follow link to find out more information: https://www.machinerychinese.com/insulating-glass-auxiliary-machine/

Info de Compagnie

- Nom de la compagnie: JINAN KATION TRADING CO.,LTD

- représentant: jichangpeng

- Produit / Service: Ligne de production de verre isolant , Machine à cintrer les entretoises , Robot de scellage de verre isolant , Verre Lifter , Machine de découpe de verre , Machine à laver en verre

- Capital: 3000000RMB

- Année d'Etablissement: 2009

- Volume total annuel des ventes (en millions de US $): US$2.5 Million - US$5 Million

- Pourcentage des exportations: 41% - 50%

- Total volume d'achat annuel (en millions de US $): Below US$1 Million

- Nombre de Lignes de Production: 3

- NombrNombre du Personnel de R&e du Personnel de R&D: 11 -20 People

- Nombre du Personnel de QC: 5 -10 People

- Service d'OEM fourni: yes

- Superficie de l'Usine (mètre carré): 10,000-30,000 square meters

- Adresse de l'Usine: Qihe

- Personne À Contacter: Ms. June

- Numéro De Téléphone: 86-0531-18678875966

Envoyer à ce fournisseur

Premium Related Products

autres produits

Produits phares

Machine de découpe et coupe-fil à câbles coaxiaux automatiques haute précisionMachine de découpe numérique (ZDQG-6100 / JQ-6100)Machine à sertir semi-automatique à bornes (SATC-20)Machine de sertissage de terminal automatique (deux extrémités) (JQ-1)Machine de découpage et décapage des câbles (ZDBX-1)Système de coupe de tubes ondulés (ZDQG-6600)Machine à sertir à commande numérique (NCPP-20H)Machine à sertir entièrement automatique (une extrémité) (JQ-5)Machine automatique de découpage et décapage de fil informatisé (ZDBX-15)Dispositif d'alimentation par câble mince à haute qualité à vendre (WRS-HS)Dispositif d'étanchéité étanche semi-automatique à faisceau de câbles automatique (Wp-01)Machine à découpage et découpage par câble platTerminaison automatique de l'alimentation latérale Moulage sous pression Pressage Pressage du moule (CA-20S)Outil de sertissage du terminal de tuyau de câble semi-automatiqueMachine à outils de découpage à découpage par sertissageMachine automatique de coupe, de dénudage et de torsion